There have been many improvements over the decades to increase the performance and decrease the emissions of the engine. Some of the technology has been listed below.

1. Hybrid Vehicle

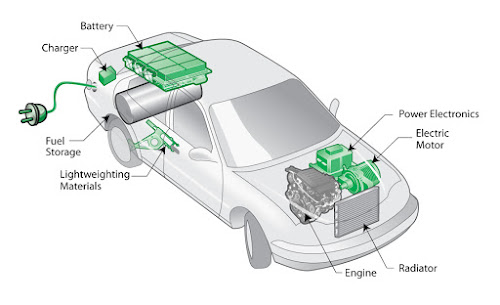

Hybrid vehicles are also known as the 'Hybrid Electric Vehicle' are popular for their higher efficiency, lower fuel cost and lower carbon dioxides. It uses both fuel and electricity. An internal combustion engine, electric motor, and batteries are combined to provide energy to the vehicle. They work in a harmony to make an efficient system. The internal combustion engine has two works. The first work is to provide the power to the motor and the second is to charge the battery. Electric motors are located in different places in the vehicle. They are connected to the transmission and driven wheels. Batteries are used to store energy. In hybrid vehicle battery charging from home or grid is not required because of the charging management system in the vehicle. All these different systems work together through the computer or series of computers. The control system decided from where the power is coming and going. Control system analysis a thousand times per second of the state of the charging system and figure out what the car has to do.

|

| Main Parts of the Hybrid vehicle |

2. Direct Injection (DI)

Direct injection (DI) is the technology in which fuel is directly sprayed inside the combustion chamber of the engine. In port injection technology the fuel comes at the backside of the valve and then goes to the combustion chamber. DI technology combines with the electronic and does the great things which are not possible with the mechanical injection system. DI precisely spray the fuel and air inside the individual cylinder of the engine with the help of electronics. The quantity of the fuel is also measured and control by the electronic fuel injection. This new technology provides high torque, better fuel efficiency, and emission regulations. however, it increases the carbon deposits on the valves. The injector of the direct injection is expansive to the port injection because of the high temperature, high pressure, and high flow rate required with this injector.

3. Turbocharging

The history of the turbocharger is old. Earlier it was used a lot in sports cars. In today's time turbocharger is used to increase engine efficiency, reduce fuel consumption, and lower emissions. A turbocharger is a forced induction device that improves the performance and emissions of the engine. It is the process of forcing compressed air into the intake for combustion. The turbocharger is designed to rotate over 1 lac RPM. With a turbocharger introduced the exhaust gas from combustion turns the turbine wheel. This turbine wheel rotates the compressor wheel which is attached by a connecting shaft. This compressor sucks the more air and sends it to the combustion chamber. A turbocharger provides more fresh air to expand on combustion and produces more power. Fresh air makes human's lungs healthy in the same way highly compressed, highly hot and fresh air make the engine more powerful.

The 'supercharger ' is driven mechanically (belt, gear, etc.) by the engine. While there is no mechanical load on the engine through the turbocharger because the turbine is driven by exhaust gases.

|

| Working of turbocharger |

4. Cylinder Deactivation

Cylinder deactivation technology is also known as 'displacement on-demand' and fuel management system. This technology is used on big engines like 6 cylinders or 8 cylinders. In light-load driving situations such as on the highway. The cylinder deactivation engine shuts down 2 or 4 cylinders to save fuel. To do this engine control units continuously analyze the following parameters such as torque, engine speed, vehicle speed, gear engaged, etc. and send feedback to the engine valve for taking action. Electronic throttle is a part of the solution it manages change over RPM. Cylinder deactivation technology shuts off one, two, or four-cylinder when cruising to reduce fuel consumption and emissions. For example, if you are driving a V8 engine on the highway (low load condition). There is not much power and torque required on this cruising therefore engine automatically deactivates the 2 or 4 cylinders to save fuel and come back to activate condition seamlessly. It is quite clever technology.

5. Electric Vehicle (EV)

Electric vehicles (EV) are becoming popular nowadays. All-electric vehicles have an induction motor and inverter instead of an internal combustion engine. The vehicle uses a large traction battery pack to power the electric motor and must be plugged into charging stations. An electric vehicle does not contain the typical liquid fuel components such as fuel tanks, fuel pumps, etc. An electric vehicle does not emit any harmful emissions. But the production of electricity produces harmful gases to the atmosphere. However, EV directly produces zero emissions. The big drawback with EV is the battery and recharging stations. All over the world governments are trying to create proper infrastructure for EV in their country.

Gorgeous concept of cylinder deactivation

ReplyDeleteThank you for your appreciation.

DeleteThank you for the compilation of these article. My question is thus, if superchargers are driven by exhaust gases, and no loads are applied, does this statement mean it's more efficient and powerful compared to superchargers?

ReplyDeleteDear Gbotemi

DeleteYes, The concept wise turbocharger is more efficient then the supercharger because turbocharger is driven by the exhaust gases of the engine.

But there are some points on which the supercharger is better than the turbocharger.

1. Oil consumption is low in supercharger

2. Supercharger give more stable and continuous power response

compare to the turbocharger.

Summary

If you want a efficient and more mileage then you can go with the turbocharger.

But if you want the more refinement in the engine (excellent torque, power) and good response of the your accelerator then you can go with supercharger.